Approximately one quarter of all edible aquatic food is discarded. At Seagarden, we’re battling this wastefulness head-on by sourcing the finest byproducts from the fishing industry and unlocking their potential.

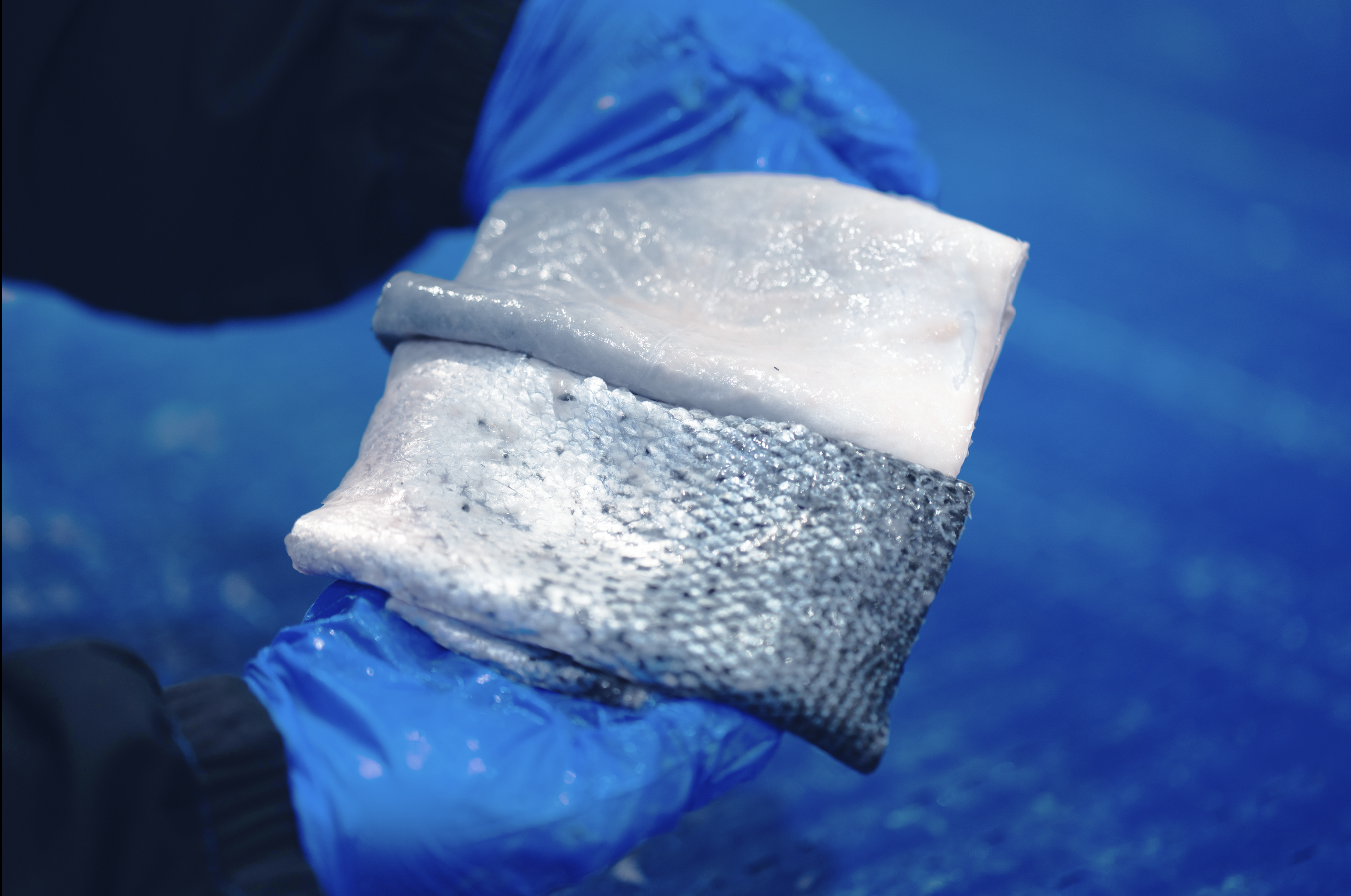

“Our premium collagen is made from fish skin from the fish processing industry in Norway. We also use other trimmings such as the backbone, head, and even shrimp shells in our various marine ingredients”, says Sales Manager Collagen at Seagarden, Eryk Czapp.

By partnering with Seagarden, you are contributing to a more circular marine industry.

“In 2021, global edible aquatic food loss and waste was estimated at approximately 23.8 million metric tonnes, equating to nearly 15% of the total aquatic food produced that year.”

–World Economic Forum: Investigating Global Aquatic Food Loss and Waste

The Environmentally Conscious Choice

According to a report from the World Business Forum, the primary sources of aquatic food loss are production (wild-capture fisheries discards) and processing on land, which together accounted for 74.46% of global edible aquatic food waste in 2021. This is the stage where skin is typically separated and, if not utilized, becomes waste.

In this context, fish skin becomes a key byproduct in efforts to reduce overall aquatic food loss and waste. By purchasing collagen from Seagarden, you support a part of the aquatic value chain focused on eliminating waste in the areas that contribute most to the problem.

Replacing Less Sustainable Collagen Sources

Globally, fish skin serves a variety of purposes, including animal feed, fashion, and cosmetics.

“At Seagarden, we believe in maximizing the potential of byproducts by directing their use toward high-value applications. Therefore, we use the complex molecular components in fish skin to create products that benefit the health of people, as well as our environment,” Czapp says.

For example, the unique molecular composition of fish skin shows significant health benefits and is a key ingredient in the progress of the nutraceutical industry.

“By adding a marine collagen source to the market, we also replace less sustainable sources of collagen, such as bovine collagen from cows,” he adds.

In short, using fish skin for human-grade collagen production is a form of upcycling that captures the material’s maximum potential and replaces less sustainable materials in other industries.

An Untapped Economic Potential

Seagarden’s clients participate in a market experiencing unprecedented growth.

The global marine collagen market was valued at USD 1,167.3 million in 2024 and is projected to grow from USD 1,262.3 million in 2025 to USD 2,316.2 million by 2032.

Considering its superior bioavailability and sustainable value chain—which appeals to environmentally conscious consumers—our premium marine collagen can be viewed as an important investment in the future of your company.